Laser welding technology has transformed the industry with its accuracy, speed, and adaptability. These Comparing 3-in-1 Laser Welding Equipment are popular because they integrate various welding tasks into one instrument. How do you choose the perfect model with so many options? This page details the characteristics of various computers and how to compare them.

What is a 3-in-1 laser welding machine?

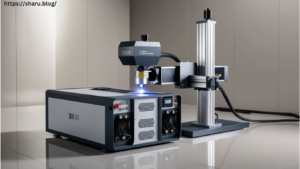

Flexible Comparing 3-in-1 Laser Welding Equipment combines different welding techniques. Laser-based machines weld cut and engrave. This functionality streamlines the process cuts expenses and saves space. The 3-in-1 machine handles materials precisely and easily in automotive electronics and jewellery manufacture.

Versatility of Functions

A striking characteristic of the 3-in-1 laser welding equipment is its versatility. Welding joins metals, whereas cutting separates them precisely. However, engraving is perfect for detailed drawings and marks. Manufacturers with financial or space constraints who require several processes benefit from this multi-functionality. One machine instead of numerous specialized units may boost manufacturing process efficiency.

Space-Saving Design

Another feature of comparing 3-in-1 laser welding devices is their compactness. One unit with several functionalities is helpful in space-constrained sectors. Due to their size and complexity, traditional welding and cutting equipment needs specialized spaces or rooms. Manufacturers may save floor space by consolidating equipment using a 3-in-1 device. This is crucial for small workshops and startups trying to optimise output without losing performance.

Cost Efficiency

A 3-in-1 laser welding machine may cost more than single-function equipment, but the long-term savings make it a good investment. Companies save money by merging three critical activities onto one machine. Since there is just one unit to maintain, operating costs may be further reduced. Due to labour consumables and space savings, a 3-in-1 laser welding system may be more cost-effective over time.

Key Features to Look For in 3-in-1 Laser Welding Machines

Consider some crucial qualities when comparing 3-in-1 laser welding equipment to choose the best one for your requirements. These include laser power accuracy, cooling, and UI. Each of these aspects affects machine efficiency, quality, and usability.

Laser Power and Performance

When choosing 3-in-1 laser welding equipment, laser power is crucial. Laser strength influences its capacity to weld or cut materials. Lasers with more power can treat thicker materials quickly. Low-power lasers may be better for thin materials or precise applications. For welding, cutting, and engraving flexibility, use a machine with changeable power settings. Laser power varies from 100W to 2000W with industrial applications using the upper end.

Precision and Accuracy

Precision is key in electronics and aircraft. To maintain product compliance, 3-in-1 laser welding equipment must achieve exceedingly small tolerances. Engraving requires precision for crisp, sharp designs. Precision optics and control systems in modern laser welding systems reduce the need for repair or corrections after each weld. Before buying, evaluate the machine’s micron-level precision to see whether it meets your needs.

Cooling Systems

Laser welding produces a lot of heat, which may influence equipment performance and lifetime. Thus, a good cooling system is necessary. For constant performance and protection of delicate components, choose a computer with an effective cooling system. Most current 3-in-1s are air- or water-cooled. For high-power systems, water cooling is suggested, although air cooling is fine for lower-power devices. A good cooling system helps extend machine life and decrease maintenance.

User Interface and Controls

A 3-in-1 laser welding equipment should have an easy-to-use interface. With numerous tasks in one device, the operator must fluidly move between welding, cutting, and engraving. Choose a machine with a touch screen or control panel that provides clear instructions and settings for each operation. Advanced systems include bespoke programming software to let operators set settings and monitor machine performance. New users may learn faster with a responsive, simple UI.

Materials Compatibility

If you operate with several metals and alloys, a 3-in-1 laser welding machine’s material compatibility is vital. Laser welding uses stainless steel, aluminium, titanium, and copper. Some modern systems can handle polymers and ceramics. Consider if the machine can handle your application’s materials. A machine with customizable material settings is more flexible and can adapt to future production demands.

Weld and Cut Quality

Another important consideration is a 3-in-1 machine’s welding and cutting. High-quality welding produces clean, smooth seams with little spatter. Laser cutters must also cut precisely and smoothly. Machines with fine-tuned settings provide better welding bead profiles and cut surfaces. Post-processing features like polishing or deburring increase product quality in certain systems. Test the machine’s capacity to create high-quality output if your application demands aesthetics.

Maintenance and Support

Every industrial piece of equipment needs maintenance, including a 3-in-1 laser welding system. Maintenance-friendly machines with self-diagnosis systems or readily changeable components save time and money. Also, consider manufacturer customer support. Extended warranties, software upgrades, and on-site repairs are available from certain firms. Before buying, check support services and replacement parts availability.

How to Choose the Right 3-in-1 Laser Welding Machine for Your Business

Your present and future demands must be considered while choosing 3-in-1 laser welding equipment. The correct machine should match your material’s project complexity and long-term production objectives. To guarantee you’re buying a system that will function well for years, study and compare models from various manufacturers.

Budget Considerations

A 3-in-1 laser welding equipment may appear expensive, but consider its overall cost of ownership, including maintenance energy use and training. Many high-end models cost more but are more efficient, lowering running expenses. Consider your budget, but investing in a more costly, higher-quality model may provide greater returns and fewer difficulties.

Customization Options

Some manufacturers let you customize the machine to your requirements. Software customisation attachments for handling particular materials and cooling or control system changes are examples. Your machine will be more valuable if you customize it to match industrial needs.

Training and Learning Curve

Consider the machine’s learning curve. Certain 3-in-1 laser welding devices are suited for novice operators, while others need more advanced training. Manufacturers typically provide in-person or online training to assist consumers in learning the machine’s functionality. Provide your crew with the resources to run the equipment safely and successfully.

Final Thoughts:

In conclusion, choosing the correct Comparing 3-in-1 Laser Welding equipment is crucial for every organization. Choose a laser with high power accuracy material compatibility and simplicity of use to improve productivity. Check cost maintenance and support to be sure the equipment will satisfy your demands today and in the future. A good 3-in-1 laser welding equipment can boost efficiency save expenses and give you a competitive advantage.